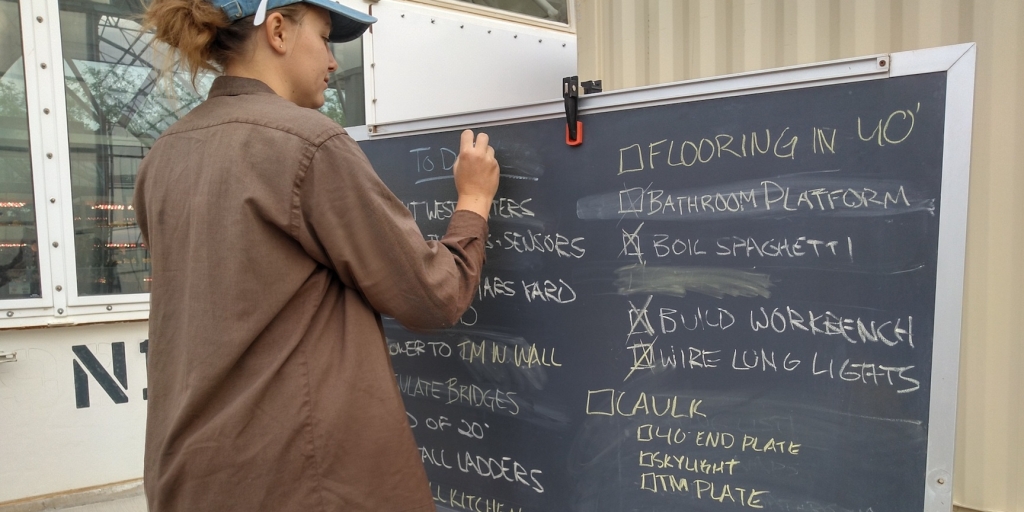

Bringing Phase II Construction to a Close

In the final days before the Analog Astronaut Conference 2022, hosted at Biosphere 2, the SAM construction and fabrication team worked tirelessly, from sunrise to sunset to get as much of SAM ready as possible for the more than 100 attendees. While most of the effort was on the task list for Phase II, some undertakings were temporary, a light treatment of a room or space to provide visitors a glimpse of what will come.