Analog Astronaut Conference 2025 concludes

The Analog Astronaut Conference has enjoyed its fourth year at Biosphere 2. This assembly of artists, writers, innovators, engineers, teachers, researchers, do-it-yourselfers, medical professionals, and yes, people who have made it to the edge of the Earth’s atmosphere and into orbit came together once again to share food, stories, science, and the warmth of direct conversations.

At a time when it seems the world is pushing everyone apart, it is comforting to be in the presence of people from so many countries—Armenia, Germany, Poland, England, Columbia, Argentina, Canada, Mexico, Kenya, the United States and more—to receive the music of accents of a half dozen languages during breakfast, lunch, and dinner. The subject matter of the talks ranged from diversity and inclusion in future human space travel to the science of CO2 scrubbers, from home-grown greenhouse structures built from repurposed water tanks to emotional intelligence as a tool for human interaction in the confines of an isolated habitat.

The SAM staff hosted three workshops:

- Basics of Wound Care and Suturing by David Wexler, MD and Dr Bindhu Oommen, MD

- Bioregenerative Life Support with Hydroponics by Atila Meszaros and Luna Powell

- A Mars Geology Tour by Dr. Christopher Hamilton and Tasha Coelho

The Wound Care workshop was hosted in the SAM Operations Center. The Hydroponics workshop was hosted in the SAM Test Module. And the Mars Geology workshop was hosted in the SAM Mars yard.

In addition, five SAM team members gave expert talks on a wide variety of subject matter:

- Kai Staats opened the conference with review of the past year at SAM and a look to the future as the SAM team transitions from construction into research for bioregeneration, air revitalization, and advanced medical care for long-duration missions far from Earth.

- Arizona State School of Earth and Space Exploration Planetary Geology undergraduate and SAM team member Tasha Coelho gave a talk about the current science investigations on Mars.

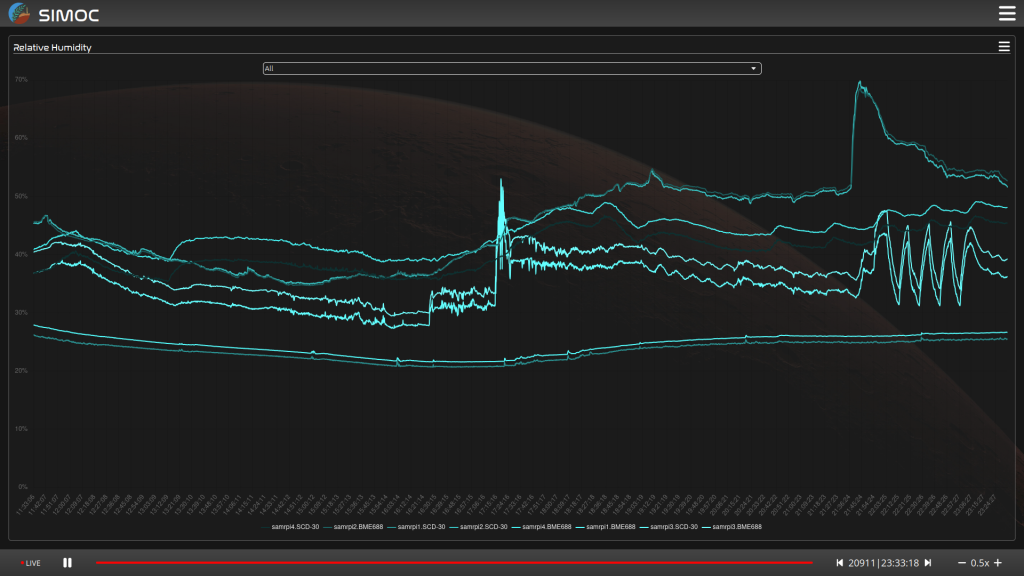

- Purdue graduate and new Mechanical Engineer at SAM Griffin Hentzen gave a talk about the new Experimental Air Revitalization Laboratory (EARL) room and carbon dioxide removal system being built at SAM.

- Bryan Versteeg, world-renowned space architect and member of the SAM team since 2019 gave a talk about his life’s work in helping envision the future of our species as we learn to live in free space and on the surface of the Moon and Mars.

- Thomas Hoffman of the new Surgical Bay Research Group at SAM (with David Wexler and Bindhu Oommen) gave a talk about the history and current state of aerospace medicine for spaceflight.