Let’s get this thing done!

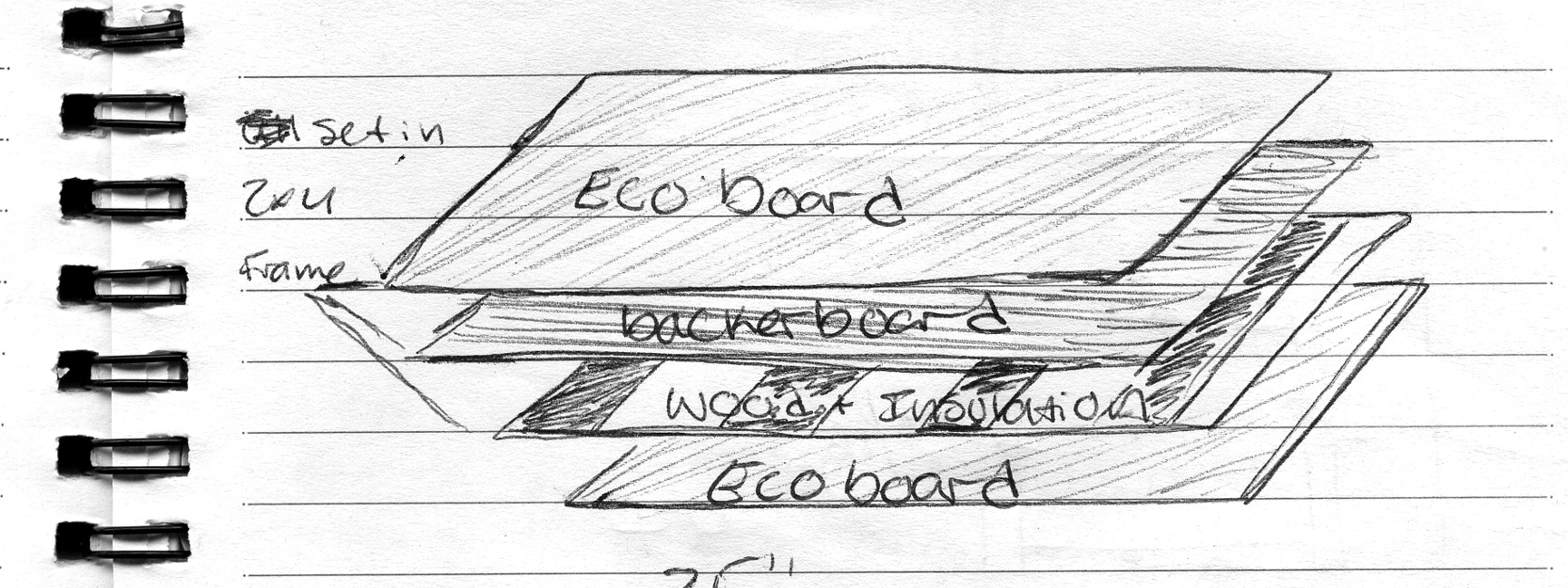

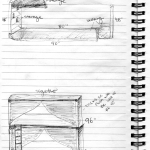

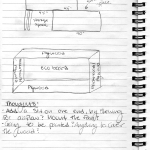

John Z., Luna Powell, and Kai Staats have arrived to Biosphere 2 for a final three months construction sprint, working sunrise to sunset (and then some) to complete this high fidelity Mars habitat research station at Biosphere 2. We have until the close of 2022 to complete fabrication and testing of the expanded pressurized vessel, electrical wiring, plumbing, and interior layout with January for extended testing and fine-tuning of systems and procedures before receiving first teams in 2023.

John Z., Luna Powell, and Kai Staats have arrived to Biosphere 2 for a final three months construction sprint, working sunrise to sunset (and then some) to complete this high fidelity Mars habitat research station at Biosphere 2. We have until the close of 2022 to complete fabrication and testing of the expanded pressurized vessel, electrical wiring, plumbing, and interior layout with January for extended testing and fine-tuning of systems and procedures before receiving first teams in 2023.

We look forward to returning team members Atila Meszaros, Sean Gellenbeck, Anastasia Stepanova, and Grant Hawkins, and new additions Ezio Melotti, Bindhu Oommen and Nathan Schmit.

Stay tuned for photos, stories, and data!