Crew Inclusion II – Microgreens, apple pie, and 3D printed chess

Hello Brenda and everyone,

Hello from Mars! We are continuing to rock it, I think. So, today I tried to take the next step in growing our microgreens. Brandy kindly brought us Hamama brand microgreens, and the broccoli is bursting at the seams. The label says to remove the cover today. I assumed that I could just pull the brown paper off the top, but it’s attached by some kind of gel to the entire root system. So I don’t know what it means to remove the cover, and the directions are probably on the box that we don’t have. Can you help?

Also, National Apple Pie day is coming up, so we would like to bake one. I think a pie crust is impossible without fat, so I was thinking of doing an apple crumble with dehydrated (rehydrated) apples on the bottom and a crumbly topping made of oats, hazelnuts, crushed shortbread cookies, maybe pretzels, and possibly applesauce to make it cling together. Could you please send an Instant Pot recipe for apple crumble?

Also also, Sahda would like .STL-.3MF files for chess characters (king, queen, bishop, knight, rook, pawn) for the 3D printer. She says it’s not a good idea to get a file for a whole chess set, because then she would have to print the whole thing (and we don’t need a chessboard). But if we have a file for each kind of chess figure, we can print them individually and maybe only print a couple and future teams could print more. It’s National Chess Day, as I’m sure you knew 😉

Also also also, the 3-D printer came with a nozzle cleaner that looks like the love child of a sewing needle and the swab you stick up your nose in a COVID test. She doesn’t know how to use it. The printer type is a Creality Ender-3S1 Pro. Could you please find instructions for using it?

Thank you so much!

Keridwen

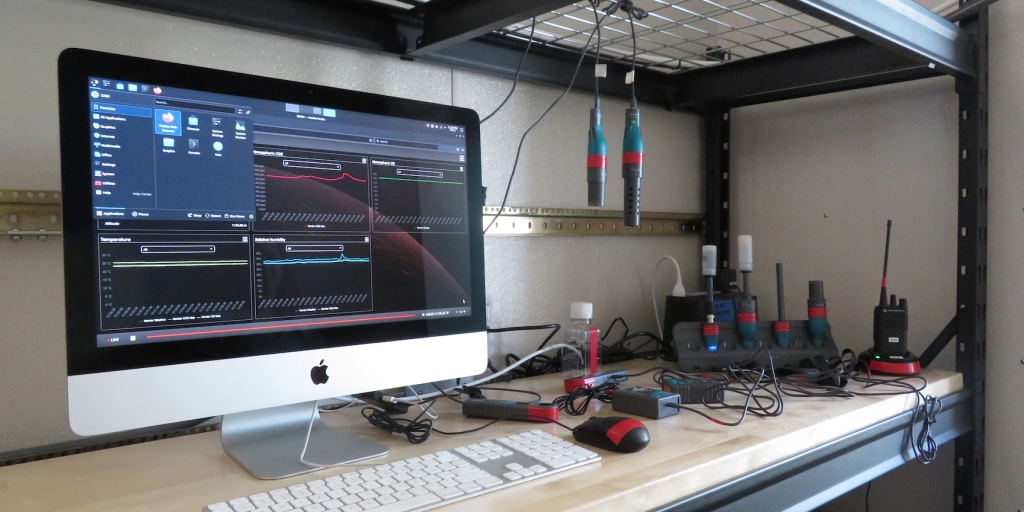

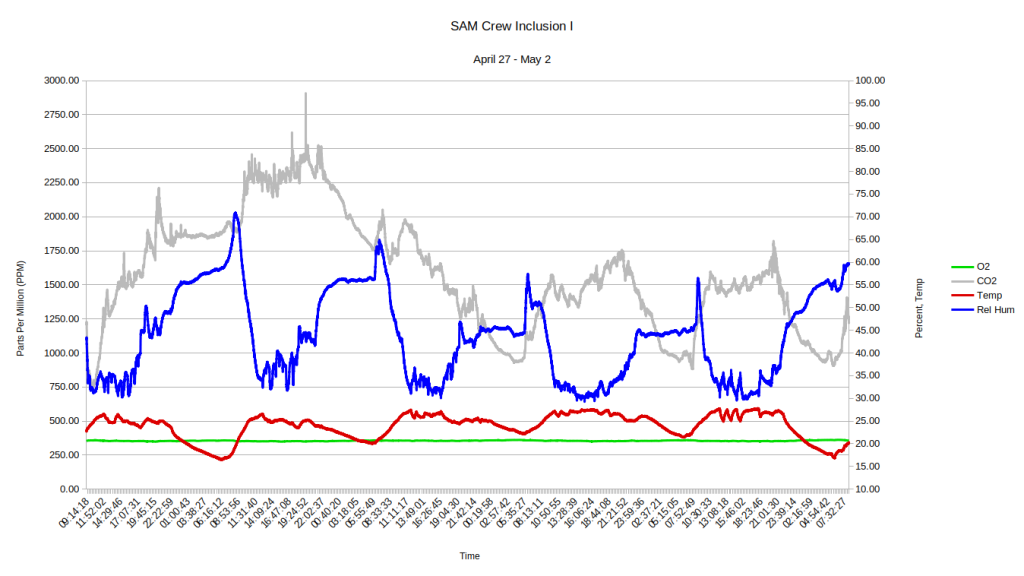

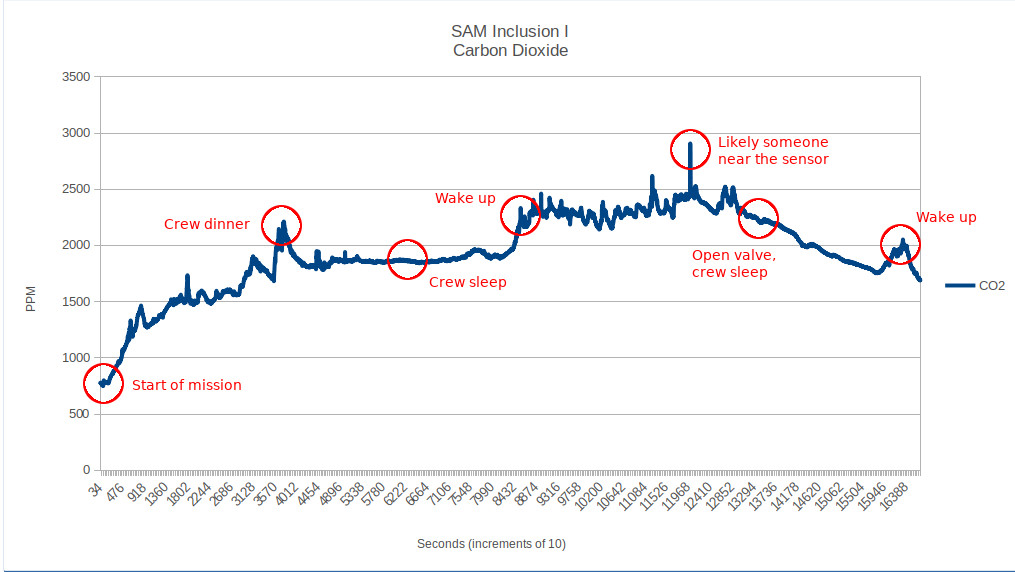

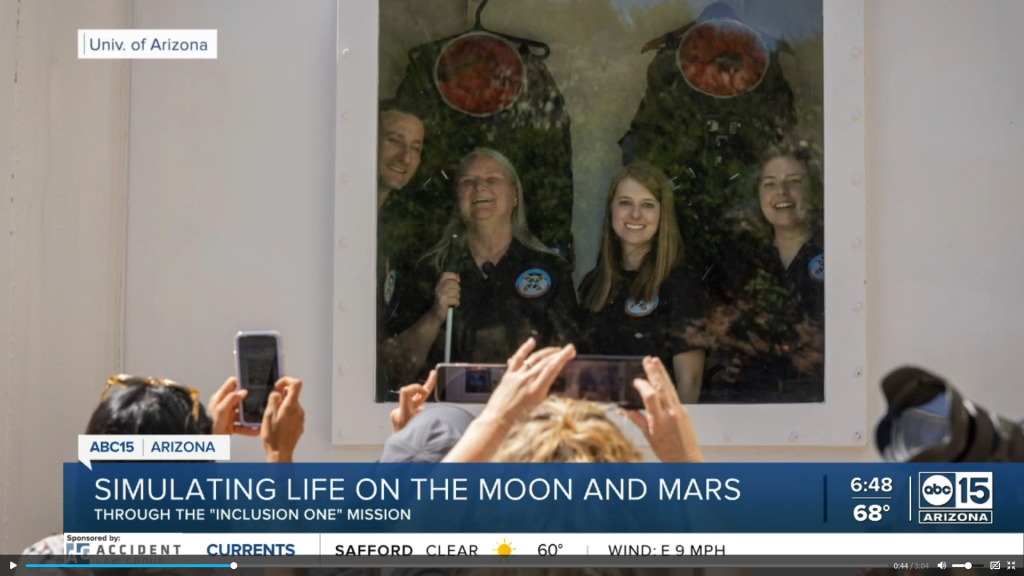

As with the first crew to enter SAM, Inclusion II underwent an extensive training in the function and operation of SAM prior to entry. Given the feedback and experience of training the first crew, the training time was expanded to a four-hours introduction to using air quality sensors and monitors, capturing the storing data, followed by a brief course in the donning and doffing of a pressure suit prior to the actual EVAs. The second full day (today) saw the crew training in:

As with the first crew to enter SAM, Inclusion II underwent an extensive training in the function and operation of SAM prior to entry. Given the feedback and experience of training the first crew, the training time was expanded to a four-hours introduction to using air quality sensors and monitors, capturing the storing data, followed by a brief course in the donning and doffing of a pressure suit prior to the actual EVAs. The second full day (today) saw the crew training in: