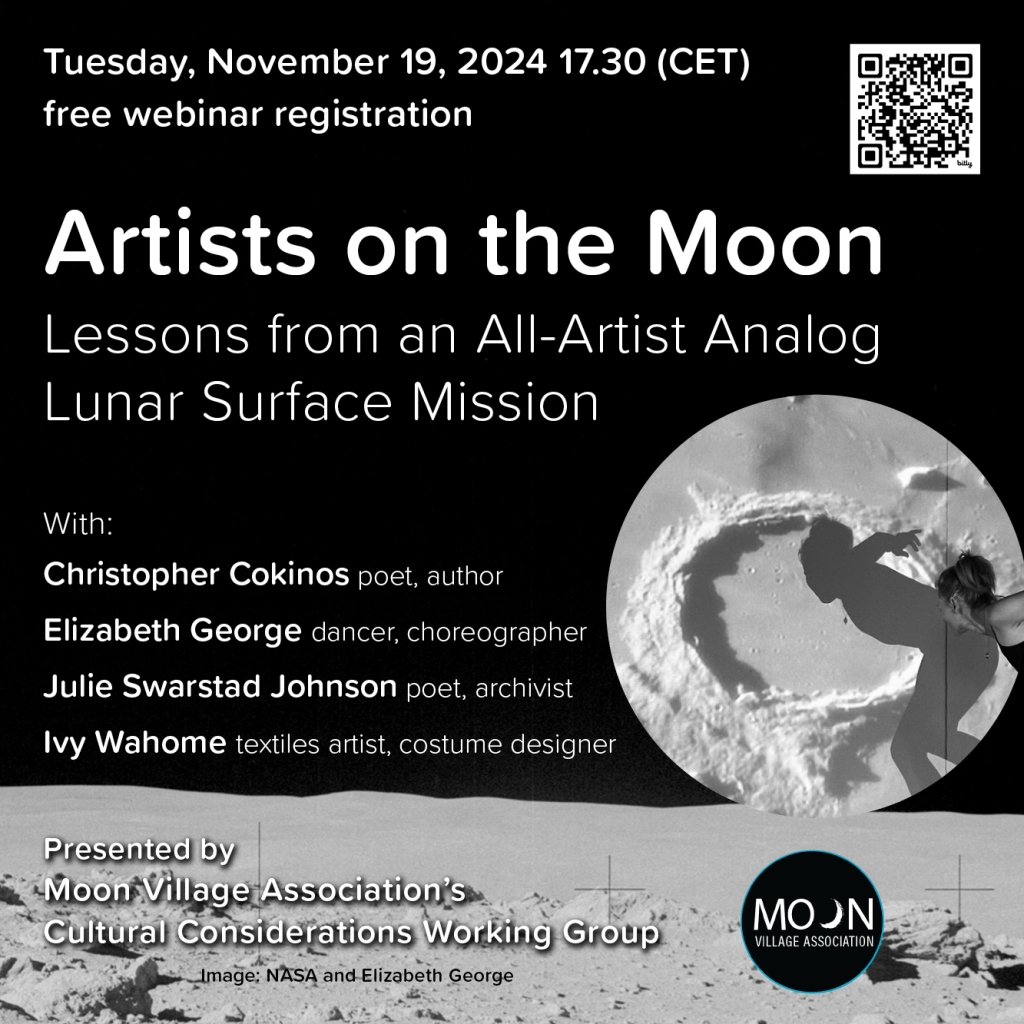

Artists on the Moon

We are aesthetic animals, and art is integrated to what we are and who we are. So, if that is the case and if we do research to understand what we are, then why don’t we integrate art into R1 science research in universities? The University of Arizona, College of Fine Arts Associate Research Dean, Ellen McMahon and her collaborators sent four artists to an analogue space mission in Biospehere2 in their Space Analog for the Moon and Mars . In this story, we will see what happens when artists enter a space habitat, that was designed for scientists.

Producer: Özlem Ayşe Özgür

Videographer: Danny Sax, Özlem Ayşe Özgür

Additional Videography: Arlene Islas

Editor: Robert Lindberg