Fire detection system nearly complete

When we first reached out to the University of Arizona Facilities Management Electrical Services, Fire Safety & Prevention Assistant Director Joseph Branaum for guidance on how to design and install the fire detection system at SAM, we were concerned that the unique nature of our research facility might invoke a high degree of scrutiny. While the vessel is built from steel, aluminum, and glass with very limited flammable materials inside, the fact that four people will be sealed inside with pressure hatches as exits could have raised alarm.

The first two teams to SAM will each have one blind crew member. This elevates the need for our fire detection and alarm system, beyond off-the-shelf, battery powered smoke detectors available from local resellers. Instead, SAM must integrate a fully networked, computer controlled system that raises audible and visual alarms across the habitat should any of the heat or smoke detectors be triggered. Furthermore, each exit must have an illuminated sign in the case of a power outage. We are taking that one step further, to make certain that each pressure hatch is fully lit with power loss, such that crew members can readily assist each other in egress, emergency or not.

The first two teams to SAM will each have one blind crew member. This elevates the need for our fire detection and alarm system, beyond off-the-shelf, battery powered smoke detectors available from local resellers. Instead, SAM must integrate a fully networked, computer controlled system that raises audible and visual alarms across the habitat should any of the heat or smoke detectors be triggered. Furthermore, each exit must have an illuminated sign in the case of a power outage. We are taking that one step further, to make certain that each pressure hatch is fully lit with power loss, such that crew members can readily assist each other in egress, emergency or not.

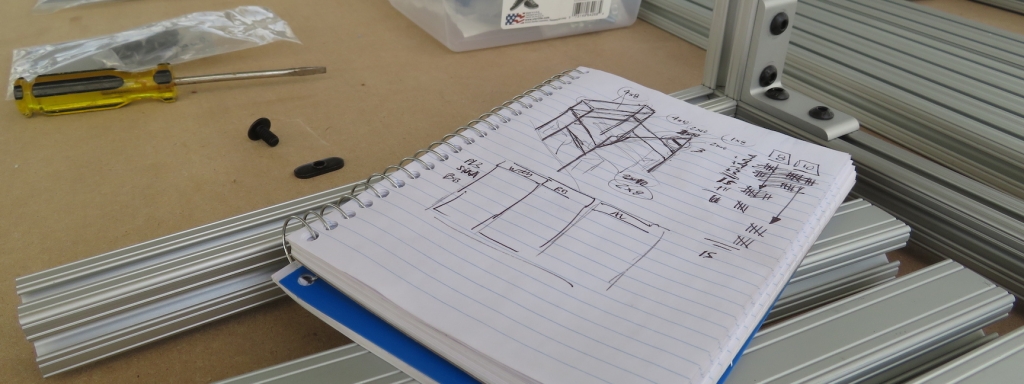

Joe visited SAM in February and immediately recognized the need for a fire detection system that met the University safety guidelines and upheld the need for SAM to closely approximate an actual, other-world habitat. He designed a system that meets code and serves our needs.

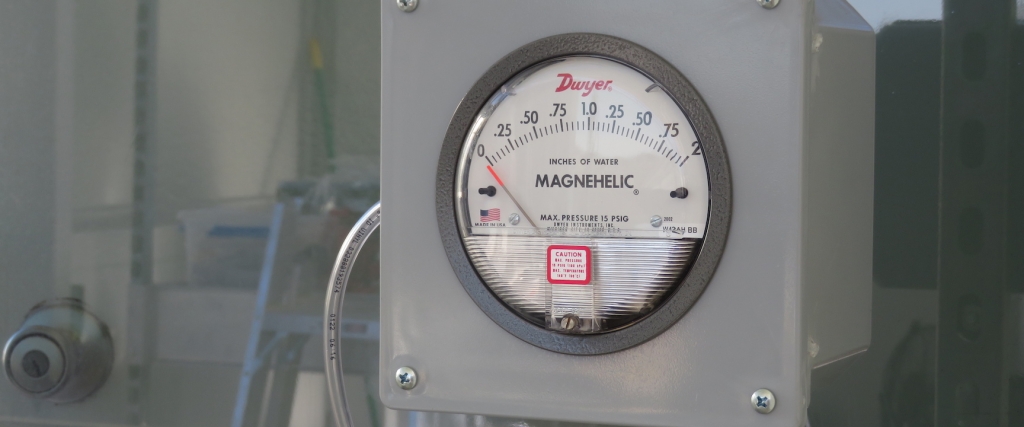

What’s more, the entire system will be upgraded later in 2023 to include active data generation and capture for real-time temperature, humidity, and air quality, then integrated into the SIMOC Live terminal at SAM, thereby elevating the SAM analog experience even closer to that of a real habitat while further informing the SIMOC model.

What’s more, the entire system will be upgraded later in 2023 to include active data generation and capture for real-time temperature, humidity, and air quality, then integrated into the SIMOC Live terminal at SAM, thereby elevating the SAM analog experience even closer to that of a real habitat while further informing the SIMOC model.

Joe and his associate Matt have guided the complex wiring of this system, and will return to SAM for the final installation of the pull stations, A/V units, and detectors. Thank you Joe and Matt for your patience with our 100+ questions, phone calls, text messages, and emails.