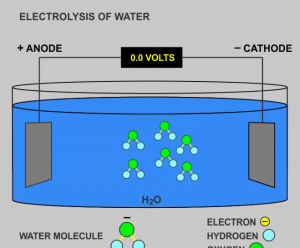

How to make fuel from ice

Science educator and writer Dan Heim answers the question, “I know there’s water ice on the Moon and Mars, and I get how it can be melted and used for drinking, but I don’t get how they can make rocket fuel out of it. — WJ, Provo, UT”

Science educator and writer Dan Heim answers the question, “I know there’s water ice on the Moon and Mars, and I get how it can be melted and used for drinking, but I don’t get how they can make rocket fuel out of it. — WJ, Provo, UT”

Dan provides an animated answer at Sky Lights …