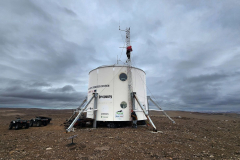

The 4-bed CO2 scrubber at SAM – Fabrication

This phase of assembly requires in-house fabrication of key, custom components, fittings, and seals. University of Arizona undergraduate students Alyssa Ackerman, Brendan Phoebe, and Jeff Buskirk joined the SAM team mid October to work along side lead engineer Griffin Hentzen, and in 2026 will assume his role, as a team, when he ends his one year engagement at SAM.

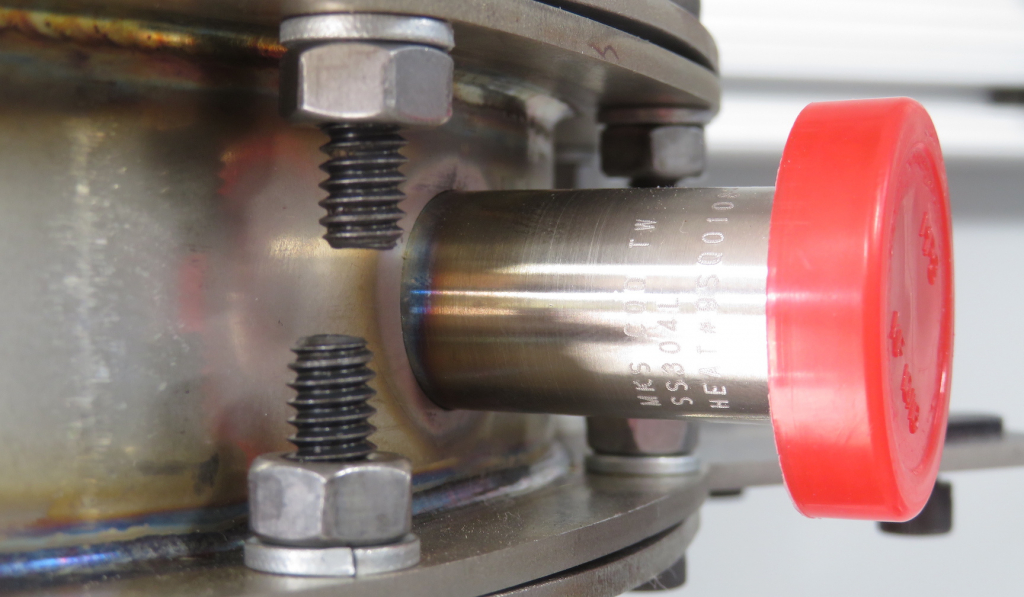

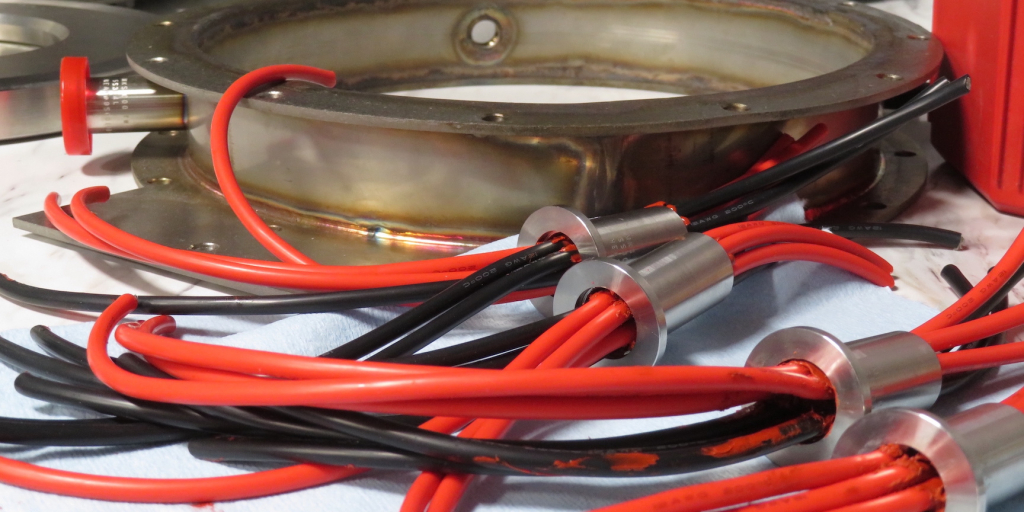

The filters, gaskets, and seals internal to the chamber stack and between the chambers, and introduction of a commodity water chiller in combination with a heat exchanger provides a closed coolant loop to maintain adequate low temperatures for maximum efficiency of the total system.

Alyssa, Brendan, and Jeff each bring a unique experience, valued skills, and confident energy to this project, and are already contributing to the overall project at an incredible rate.

Experiment | Design | Components | Assemble | Fabrication | Operation (coming soon)