Sculpting Mars at SAM: Day 9

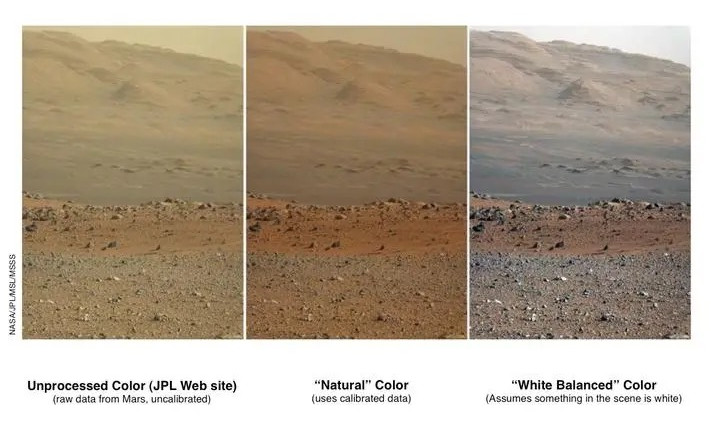

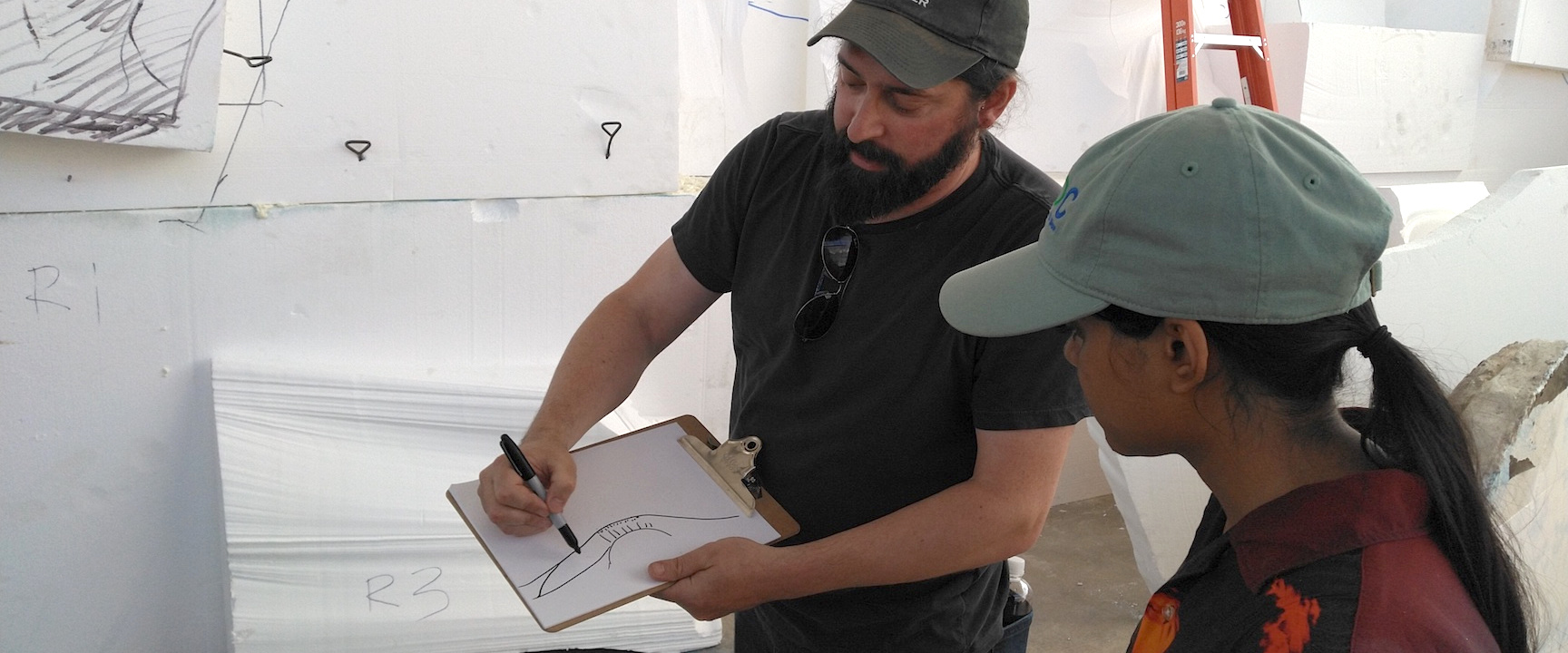

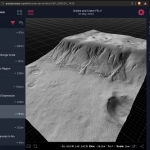

The transformation of Polystyrene foam blocks into a Mars landscape requires vision, skill in sculpting, shooting concrete, and painting; and effective management. The first and last are exemplified by Red Hen founder Danica Vallone who maintains a relationship with some 250 individuals working in set design and construction, and her brother and production manager Demian Vallone who brings patience, diligence, and hands-on collaboration to the construction floor. At the SAM Mars yard Danica and her team have transformed drawings and photographs into three dimensions, demonstrating a deep understanding of form, texture, and color and the physical tools used to employ them.

The sculptors (as noted in prior blog entries) hold what is perhaps the most challenging of the processes— making those first cuts into the massive blocks of foam with a vision toward the end product that they may never see. This process is principally one of subtracting material, cutting into square blocks to remove initially large and then increasingly smaller pieces using hot wire knives, chain saws, horse brushes, three pronged picks, and an assembly of home-built hand and power tools. Material is added too, building beyond the otherwise imposed limit of a wall or corner, as with the rockfall in the southeast corner of the SAM Mars yard.

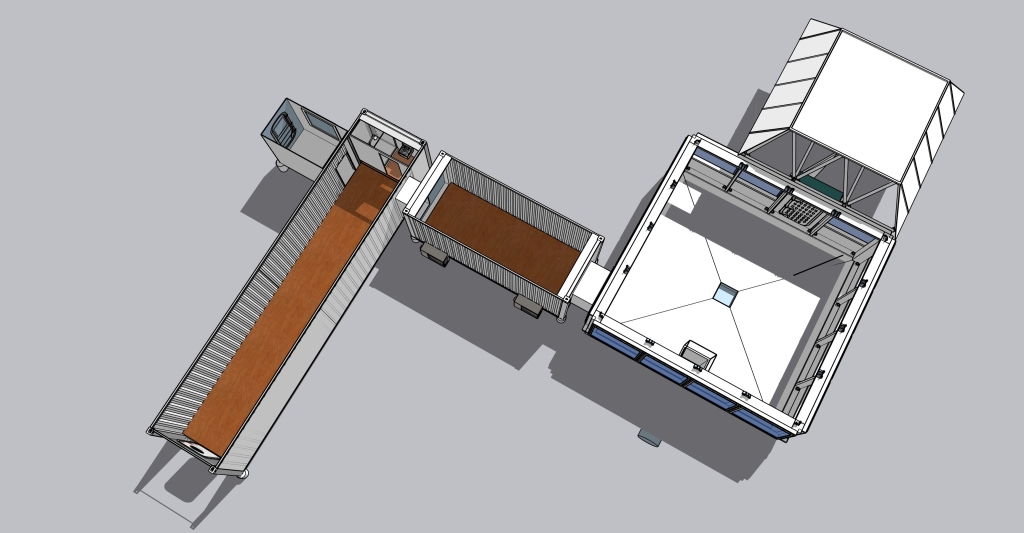

With the shapes established, the plaster crew covers the foam with a thin layer of a custom blend of Poly-bond structural concrete, sand, and adhesives designed to bond to foam. This concrete is tinted to establish a base color such that the final, painter crew can work from that base color with less effort and material, as compared to starting from a standard concrete gray.

While Hollywood sets built from foam are typically covered with 1/8″ concrete, thicker for areas on which actors might walk, the SAM Mars yard is 1/4″ nominal with the west wall K-rock covered in expanded steel, steel mesh, and in some areas up to two inches hand-troweled concrete.

Three sculptors were at SAM for eight days. The four plasterers are slated for just two days (starting today). And as of this coming Sunday two painters will be at SAM for four days. Each crew brings to this project some of the finest talent in Hollywood, with individuals who have two or three generations in skill and experience in their respective trades. The quality of production against an impossible timeline has been truly awe inspiring and points directly to Red Hen’s ability to manage such a complex endeavor.

BELOW: Luna Powell scatters real stones obtained from a local quarry on the shelves and outcrops of the north wall as the plaster team applies the first layer of shocrete to the south wall of the SAM Mars yard. The blue color is a layer of “Weldcrete”, a kind of chemical adhesive that helps the Polybond-based shotcrete adhere to the foam.