Mars yard east wall rebuild

When the original rain forest greenhouse was built in the mid 1980s, it was known that the polycarbonate panels would need to be replaced, eventually, but by whom? With one round of repair (based on a discussion with a long-time Biosphere 2 staff member), they lasted more than 30 years. But in the end, the roof and all wall panels must be replaced. This effort began two years ago with replacement of the roof (see Through the Roof and New Roof) and continues now with the four walls, the East and West in the worst shape given the intensity of the sun, wind, and rain.

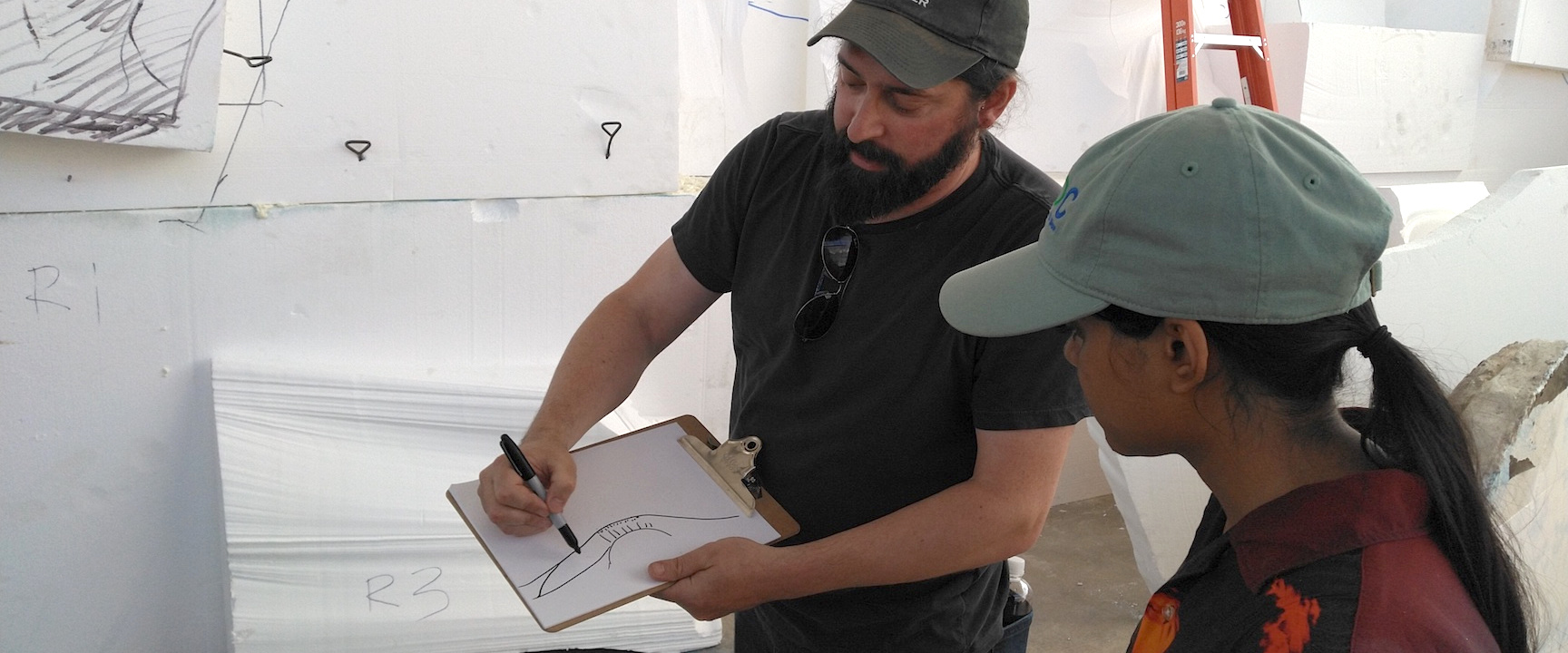

Matthias, Sean, and Luna have spent three months, juggling myriad other tasks, with this no-one-really-wants-to-do-it task. Matthias has lead the charge, holding the team to a high quality standard. There is nothing simple or easy about it, and no contractor could do a better job. Each panel must be custom cut to match width and height and curve of the overhead greenhouse arches. The top of each panel must be sealed with aluminum tape. Two kinds of screws are applied, some with sealed gasket roofing heads, other rubber backed washers to spread the pressure and keep out the water. The final product is then caulked with 795, a product that will likely outlast the new panels themselves.

The end result is stunning!