SAM is a dynamic platform and infrastructure for ever expanding research and experiential learning. It is our goal to provide visiting teams a rich personal and team experience both inside and outside of the Test Module (greenhouse) and crew quarters. Hi-fidelity, fully operational equipment and systems mirror those employed now or in near-future flight and habitation systems. The following details some of the integral components incorporated into the design of the total SAM facility.

THE SAM FACILITY

Test Module

In 1987 Test Module was built as a prototype to the Biosphere 2. This hermetically sealed space proved atmospheric and water recycling, food production, waste management, and mitigation of atmospheric pressure changes. The Test Module serves as the Controlled Environment where hydroponic and grow bed experiments are conducted, food cultivated, and waste recycled in an integrated bioregenerative life support system. Learn more …

The Lung

The Test Module lung is a variable volume, pressure regulation module composed of a 3,800 pound steel pan attached to a flexible membrane, forming a sealed lower chamber. The mass of the pan exerts a continuous, downward pressure on the column of air which in turn pressurizes all of SAM. A Variable Frequency Drive (VFD) blower enables rapid inflation of the lung and finite control over airflow during Mode 1 or Mode 2 operation. Learn more …

Engineering Bay & Crew Quarters

The Engineering Bay (EB) and Crew Quarters (CQ) at SAM extend the pressure vessel of the original Test Module into an adjacent 160 (15 sq-m) and 320 sq-ft (30 sq-m) of floor space, respectively. The EB provides visiting crew with a 3D printer, microscope, sewing machine (if needed), soldering bench, tools, and first aid kit. The CQ houses the sleeping pods, kitchen and common space, and bathroom.

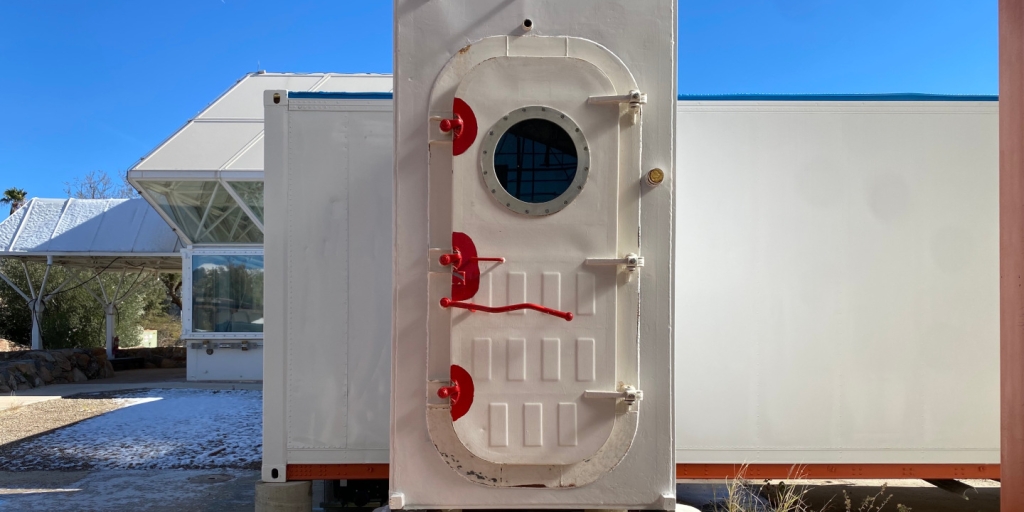

Airlock

SAM incorporates a fully functional airlock for when crew members conduct an EVA into the adjacent Mars yard, without depressurizing the vessel. The air sent to the pressure suits via umbilical is drawn from within the SAM vessel, as well as the air used to repressurize the airlock when a crew member returns.

Mars Yard

This 3000 sq-ft (~300 square meter), geologically accurate, indoor facility includes a lava tube, embedded magnetic anomalies, trace gas delivery, and a reduced gravity simulator. The Mars terrain was co-designed by Dr. Christopher Hamilton, UA Planetary Geologist and built by one of Hollywood’s Red Hen Studios. It provides visiting crew members with the challenge of exploring realistic terrain while encumbered by pressure suits. View photos …

Operations and Mission Control

The SAM Operations Center is a 1,200 sq-ft building separate from the SAM habitat and Mars yard, at the Biosphere 2 campus. Ops includes a library-den, conference room for local team and virtual meetings, full kitchen and bath, workshop for on-site repair of equipment, and Mission Control complete with projection screen for real-time data monitoring and communications. SAM Ops maintains a dedicated radio link to SAM for data relay with light travel-time delay to simulate the distance from Earth to Mars and back again.

THE SAM COMPONENTS

Hydroponics

This in-house designed hydroponics research facility was built for research in bioregeneration—the sequestration of carbon and production of oxygen by food cultivars for long-term space habitation. The rack shelves are readily adjusted, the trays swapped for low or high density, and nutrient delivery managed by a Campbell Scientific managed NFT.

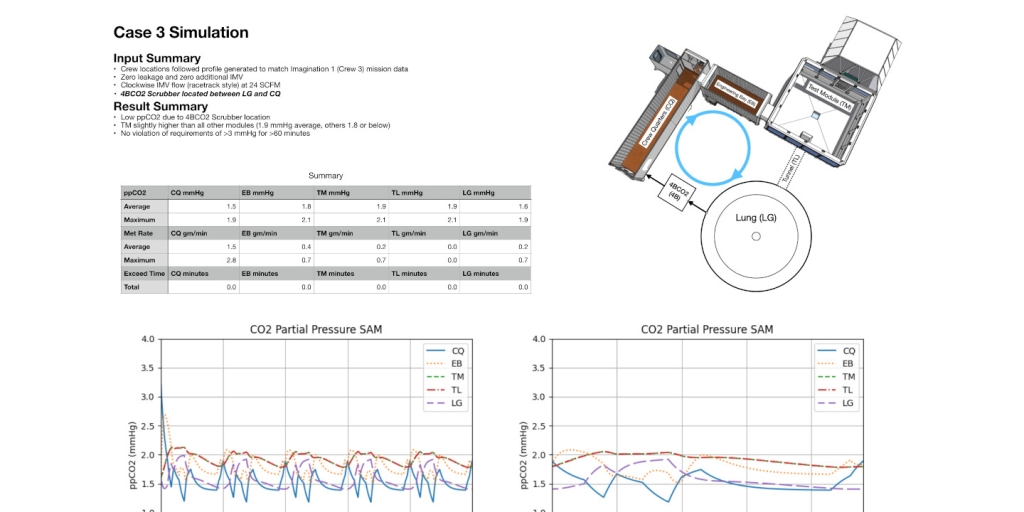

CO2 Scrubber

In the first half of 2024 Dr. James Knox, NASA veteran and designer of the scrubber running on ISS today, developed a mathematical model of the SAM airflow based on data from the first three missions (2023-24). In 2025 an entirely new facility is being built to house the SAM four-bed CO2 scrubber, and scrubbers delivered by visiting researchers. This world-class research facility will be available to academic and commercial systems tests.

Surgical Bay

Lead by Dr. Bindhu Oommen, M.D., practicing general surgeon and member of the SAM team since 2022, SAM is building a dynamic, world-class team that includes active surgeons and dental professionals, a former naval officer and NASA flight surgeon, and engineering students, to design, develop, and prototype a fully functioning surgical bay for installation at SAM.

Pressure Suits

SAM crew have at their disposal the use of two pressure suits for all EVA missions into the Mars yard. Developed by Dr. Cameron Smith of Smith Aerospace Garments, these high fidelity systems incorporate a pressurized bladder (1-4 psi over ambient) and cover-all garment for a realistic experience. The regulated airflow source can be an umbilical chord to SAM or a self-contained Mars cart with compressed air (SCUBA tank). Learn more …

Reduced Gravity Simulator

The SAM Reduced Gravity Simulator (also known as a gravity-offset rig) is a mechanical means to reduce the apparent weight of a suited or unsuited individual for the purpose of training for movement in less than 1g gravitational fields, to test equipment and procedures, and to learn how a rover might operate when moving over varied terrain in 1/3 (Mars) or 1/6 (Moon) gravity. Learn more …

SIMOC – SAM’s Digital Twin

SIMOC is a Scalable, Interactive Model of an Off-world Community. This open source, research-grade platform and educational web interface has been in development since 2017. It is a cornerstone of research at SAM—which was designed and built for the primary purpose of generating data to reinforce the SIMOC agent-based model. SIMOC Live is the air quality monitor that runs during each SAM mission, and is used to inform the SIMOC model. Learn more …

Our Philosophy | The SAM Research Station | Components | Photos | Updates