SAM Construction – Step by Step

The work at SAM continues, each day one more item checked off the list. We are nearing the point at which deconstruction gives way to construction, where our effort to break is instead to rebuild. This week Trent and Kai lowered the massive, welded I-beam platform which held the even more massive heat exchanger. Trent remove those bolts that would turn, cut the others, and disassemble the frame.

Cameron removed a complex array of wiring and conduit from the front porch of the test module, the light fixtures yet filled with water from the last rain. The heavily cracked paint was ground and sanded to remove anything lose, the edges feathered, then secured with an exterior metal primer.

SAM Construction – The physics of restoration

Today was a day for applied physics.

Today was a day for applied physics.

Starting with the angle grinder (a beast of a machine!), its function is based on (a) a high coefficient of friction between a rotating surface which is harder than the surface to which it is being applied; which causes (b) abrasion between the two surfaces, and subsequent (c) removal of material as the disc rotates at a high velocity with strong angular momentum (torque). As greater pressure is applied more material is removed, to a degree.

The challenge is to find the balance between the applied pressure and potential overheating. If the material becomes semi-molten, it is moving toward a liquid state which reduces the speed of material transfer due to reduction in friction. Hot enough to toss off small bits, but cool enough to remain solid. What baffles me is the structural integrity of those grinding discs. You can lean hard on them, directly or at an angle and they do not suffer divots nor shatter. Incredible!

Removal of the second, large gas analysis box was quite the challenge. Two times larger than the one on the east side of the north exterior wall of the Test Module, this one was equally wedged in place, the information panels clearly added at a later date. We attempted to remove all of the white “7” shaped supports but could not remove the middle two as there was simply not enough play with the box in beneath to force them loose (After thirty years of steel posts in steel sleeves in concrete, it is a miracle we got them out at all!)

Trent and Cameron used a makeshift lever to raise the box and insert threaded rod roller beneath, Egyptian pyramid style. We then attached load straps to the box, with Cameron on one and Trent and myself on the other.

Trent and Cameron used a makeshift lever to raise the box and insert threaded rod roller beneath, Egyptian pyramid style. We then attached load straps to the box, with Cameron on one and Trent and myself on the other.

“On the count of three! One … two … three—pull!”

Nothing. We tried again and again, but no go.

Then it occurred to me that my Subaru Crosstrek offers a great deal more horsepower. I backed my car. Trent attached one end of the load strap to my trailer hitch and with almost no fuel applied it came right out. What made this interesting to me is that when the box came off the rollers, my car hesitated for a moment. I had barely pressed the pedal to that point, and added a little more fuel. I could feel the power automatically transfer from one drive wheel to another, back and forth in fractions of seconds. The car was sensing slippage and correcting its power transfer accordingly. Not a mote of dust was raised other than that which was pushed by the box as it came off the rollers and into the dirt.

Then it occurred to me that my Subaru Crosstrek offers a great deal more horsepower. I backed my car. Trent attached one end of the load strap to my trailer hitch and with almost no fuel applied it came right out. What made this interesting to me is that when the box came off the rollers, my car hesitated for a moment. I had barely pressed the pedal to that point, and added a little more fuel. I could feel the power automatically transfer from one drive wheel to another, back and forth in fractions of seconds. The car was sensing slippage and correcting its power transfer accordingly. Not a mote of dust was raised other than that which was pushed by the box as it came off the rollers and into the dirt.

With the box gone the middle posts that held the information panels remained. The others came free with an application of a rust-breaking lubricant and repeated, swift kicks followed by jiggling and lifting. But the middle two were quite a bit more stubborn. As an archaeologist who best understands tool use by our ancestors, Cameron resorted to a calculated application of caveman physics—beat the [crap] out of it! It worked!

With the box gone the middle posts that held the information panels remained. The others came free with an application of a rust-breaking lubricant and repeated, swift kicks followed by jiggling and lifting. But the middle two were quite a bit more stubborn. As an archaeologist who best understands tool use by our ancestors, Cameron resorted to a calculated application of caveman physics—beat the [crap] out of it! It worked!

The removal of the dry, aged grow beds two weeks ago threw a tremendous amount of dust into the air, coating the entire interior of the Test Module. To clean the space frame and windows, Trent climbed up into the higher reaches of the Test Module using the safety harness provided by Biosphere 2. He is a former climbing instructor and as such felt right at home far above the floor. Throughout this project we have been reminded of the physics of static electricity when working with the shop vacuum. Any time we are pulling a large volume of fine dust into the plastic nozzle and corrugated tube, the acceleration of those particles in a volume of dry air causes a rapid, massive build-up of free electrons at a very high voltage (likely tens of thousands of volts, at a relatively low amperage). This presents such a challenge that if one does not maintain a hand on the metal frame at all times, the resultant shock can be quite painful. Wearing gloves only further insulates the body such that the pressure increases to make the jump. As such, Trent was hanging on for more than the obvious reason.

The removal of the dry, aged grow beds two weeks ago threw a tremendous amount of dust into the air, coating the entire interior of the Test Module. To clean the space frame and windows, Trent climbed up into the higher reaches of the Test Module using the safety harness provided by Biosphere 2. He is a former climbing instructor and as such felt right at home far above the floor. Throughout this project we have been reminded of the physics of static electricity when working with the shop vacuum. Any time we are pulling a large volume of fine dust into the plastic nozzle and corrugated tube, the acceleration of those particles in a volume of dry air causes a rapid, massive build-up of free electrons at a very high voltage (likely tens of thousands of volts, at a relatively low amperage). This presents such a challenge that if one does not maintain a hand on the metal frame at all times, the resultant shock can be quite painful. Wearing gloves only further insulates the body such that the pressure increases to make the jump. As such, Trent was hanging on for more than the obvious reason.

SAM Construction – On orbital sanding

Dr. Cameron Smith from Portland State University has arrived to Biosphere 2 and SAM. Cameron is co-founder of Pacific Space Flight and Smith Aerospace Garments and will be delivering two pressure suits to SAM this spring. For now, Cameron is here to work along side Kai, Trent, and the Biosphere staff on the transformation of the Test Module into SAM.

The lower, exterior steel wall of SAM has held up remarkably well. Given that it yet holds the original paint and seals from 1987, there were only limited flaking and chips. The challenge was to identify loose areas of paint, remove, and then feather the edges down to the bare steel. Cameron was able to complete three sides of the exterior, some 240 sq-ft while Trent and Kai worked to safely lower the steel I-beam platform that until just a few days ago, held the massive heat exchanger.

SAM Construction – Climbing training and metal repair

As the 1987 Test Module was the prototype for the Biosphere, it was built using what proved to be an incredibly strong space frame designed by William Dempster and Taber MacCallum, based upon Buckminster Fuller’s geodesic dome. This structure is more than three decades old, yet the paint retains is sheen, the interior bolts are without rust. The structure was holding a steel platform and heat exchanger with an estimated greater than 2000 lbs weight. Trent Tresch and Kai Staats were trained by Biosphere 2 Research Specialist Jason Deleeuw in the use of full-body climbing harnesses and self-rescue equipment in order to safely conduct repair and construction of what will be the SAM controlled environment (greenhouse).

The day concluded with the removal of four steel struts, two of which held gas canisters and two other that held an airtight electrical box. Kai Staats used a metal grinder, 60 and 120 grit sanding discs, and primer to repair and smooth the surface of the steel beams in preparation for a new coat of paint.

SAM Construction – Repairing the Lung

Trent Tresch and Kai Staats work to remove 30+ years of rust and corrosion from the upper steel framework of the lung for the Test Module. This structure, built in 1987 as an engineering prototype for the Biosphere 2, includes a flexible, sealed membrane such that once inflated it maintains a positive pressure and provides an air buffer for the greenhouse structure.

When fully rebuilt, this will be attached to a corridor, workshop, and full crew quarters as the construct of a Space Analog for the Moon and Mars, or SAM at Biosphere 2.

Learn more at samb2.space …

SAM Construction – Dr. G. visits SAM!

Dr. Gene Giacomelli, Professor of Biosystems Engineering at the University of Arizona, Controlled Environment Agricultural Center (CEAC) spent two hours with us at SAM this morning. We requested his visit in order to help guide the placement of our new electrical runs, first order layout of the hydroponics, and overall considerations of safety in a moist, confined space with student researchers. We came away with a wealth of knowledge, and look forward to continued engagement.

John, Trent and I then met for an hour to discuss preliminary findings in our atmospheric composition research as it pertains to the automation of SAM’s partial pressures, and as we prepare to receive the CO2 scrubber built by Paragon, originally funded by NASA for a study of CO2 sequestration efficiency.

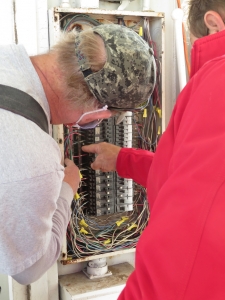

Aaron Bugaj, researcher at Biosphere 2 LEO and videographer lent us a hand for an hour, helping Trent remove the massive copper conduit from the old, elevated heat exchanger while I continued to remove old, unused electrical boxes and conduit. The result is a greatly simplified interface to our primary breaker box and 3-phase feed.

SAM Construction – At the Close of Two Weeks

This second week of the rescue, refurbish, and reconstruction of the Test Module, what will soon be the greenhouse for SAM, has been wonderfully rewarding. Where our first week found us diving into what felt like an endless chasm of relentless cleaning, grinding, sanding — wondering how we would see the end of it — the past five days found us making good progress.

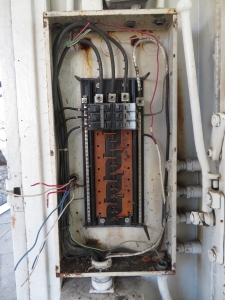

Doug, Tim, and Terry, veterans of Biosphere 2 for some three decades dove right in, with Trent and two UA graduate students Michael and KC applying jack hammer, shovel, and wheel barrow to the heavy, hard dirt. Trent, Tim, and KC worked at cleaning up our future Mars yard while another crew worked to carefully disassemble the old, massive heat exchanger in the upper reaches of the Test Module. The electrician Kevin spent a half day testing electrical circuits to determine where and how to power our revitalized greenhouse and crew quarters. Needless to say, thirty years of desert heat, occasional rains, and the teeth of mice and rats are not kind to wiring. Much of what exists will be pulled and re-run.

Sadly, I spent most of the week with fingers to the keyboard writing a grant proposal with Kevin Bovine, Director of Education and Outreach for Biosphere 2 while Trent and crew had all the fun — Kai Staats

SAM Construction – Down the rabbit hole!

“The rabbit-hole went straight on like a tunnel for some way, and then dipped suddenly down, so suddenly that Alice had not a moment to think about stopping herself before she found herself falling down a very deep well.”

We know the rabbit hole is deep, very deep, seemingly bottomless at times. And as we fall, as Alice did, we have time to look around, to take in the scenery. But instead of cupboard, bookshelves, and marmalade, Trent and I see rusted steel, chewed wires, junction boxes that need replacing; grinding, sanding, priming, and painting before we can begin to put it all together again.

Yet, this is the most fun we’ve had in a long time!

As Alice thought to herself, `after such a fall as this, I shall think nothing of tumbling down stairs! How brave they’ll all think me at home! Why, I wouldn’t say anything about it, even if I fell off the top of the house!’ (Which was very likely true.)

Building SAM is no easy undertaking, but nothing easy is ever as gratifying as something hard. And therein lies the pleasure in the pain, the joy in confounding, for each and every day our vision becomes a little bit more clear. We see how a particular panel can be reused, how with a little effort a seal can be made like new, and how our replacement of 1980s technology with modern equivalents will consume less space and less power, and if we do our jobs right, will be more easily replaced for future upgrades.

“I removed some three dozen circuits, salvaged several hundred feet of 12g wire, and then installed four temporary circuits for our construction effort. I never tire of tracing the mess of wires, removing unused runs, and flipping a breaker for the first time to see the lights turn on. I can explain the transfer of electrons across the outermost covalent bonds of the copper, sixty times and at 300,000 kilometers per second, yet I still find electricity to be a bit magical.” —Kai

“I removed some three dozen circuits, salvaged several hundred feet of 12g wire, and then installed four temporary circuits for our construction effort. I never tire of tracing the mess of wires, removing unused runs, and flipping a breaker for the first time to see the lights turn on. I can explain the transfer of electrons across the outermost covalent bonds of the copper, sixty times and at 300,000 kilometers per second, yet I still find electricity to be a bit magical.” —Kai

Alice opened the door and found that it led into a small passage, not much larger than a rat-hole: she knelt down and looked along the passage into the loveliest garden you ever saw.

And the construction of SAM continues …

SAM Construction – A wrestling match

Today Trent and I removed one of the two original monitoring units, a semi-sealed box that contained equipment for monitoring the pressure and atmosphere compositions. This was a feet of engineering as much as brute strength. The steel boxes are heavy and were held in place by multiple conduits. Trent assembled a clever extension to a socket set that gave us a nearly four-foot reach!

The analog data was fed through a massive, multi-strand, individually shielded cable to a separate “booth”, just outside the main sealed door and under the overhang, where it was read by the team lead and visitors to the Test Module. Our intent is to retain the sealed conduit, maybe even use all or part of the booth, but instead we will run ethernet and USB, umbilical cords to the outside world.

Why not wireless? Ever tried trouble shooting a router or upgrading firmware over wi-fi? A hard line is always the right thing to have (else you get stuck in the matrix) , such that our team can interface with those on the inside, if need be, with direct lines. We are debating if we should retain the original, very large transfer box or replace it with something smaller, more water tight.