Matthias Beach enters SAM for two weeks stay

SAM team members Matthew Rusek-Peterson, Luna Powell, Matthias Beach, Dr. Linda Leigh, Atila Meszaros, Griffin Hentzen, and Kai Staats.

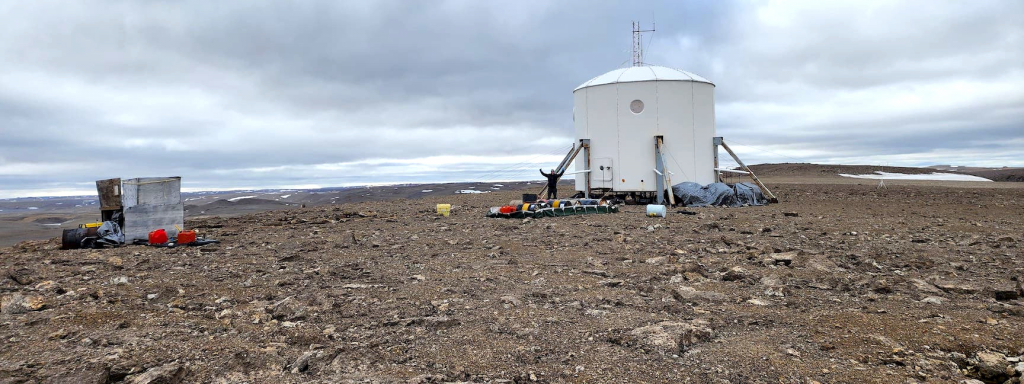

The SAM team arrived on-site at 6 AM, Luna Powel, Atila Meszaros, Griffin Hentzen, and Matthias Beach immediately diving into a list of TODOs before the solo, sealed mission began. Kai Staats joined them to replace the pump on the water manifold and configure the SIMOC Live and Vernier sensor arrays. While SAM has since April 2023 seen five crewed teams and 31 individuals for more than 126 total person days, or 3038 total crew member hours—there is always something more to prepare for the next human-in-the-loop experiment.

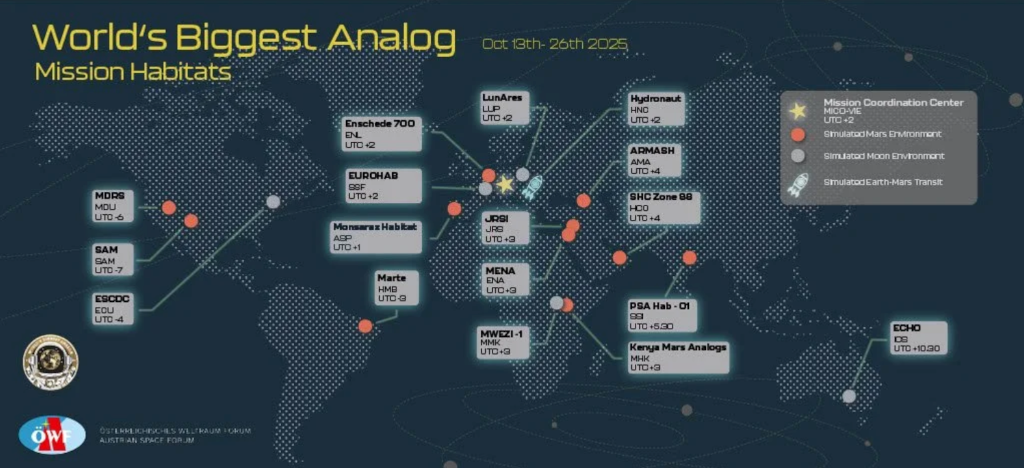

SAM is an active research center, ever growing in its capacity to support a diversity of experiments. With a series of foundational bioregeneration experiments completed this spring and summer, this solo crew member, two weeks stay is the culmination of more than seven years research, development, fund raising, and construction.

Master of Science candidate at the University of Arizona Atila Meszaros’ thesis experiment is the demonstration of the capacity for the sequestration of carbon dioxide and production of oxygen by a single food cultivar, in this case, a dwarf variety of pea developed by Dr. Bruce Bugbee at Utah State University.

SAM has from the start been guided by the original experiments conducted by the “Biospherians” from 1986-1990, while they were designing and then constructing the Biosphere 2. While several of those individuals did stay inside the Test Module, the prototype for the Biosphere 2 that now serves as the controlled environment (greenhouse) for SAM, Linda Leigh remained inside for three weeks without outside air, food, or water.

At 10:57 am Matthias Beach hefted his personal duffel bag, shook hands with Director of Research Kai Staats, and was ushered into SAM through the airlock by Linda Leigh (photos at bottom), continuing her tradition of seeing all of SAM crews into and out of SAM. Matthias’ stay will be the longest mission in SAM to date, and the first long-duration in which the pressure vessel will operate in Mode 0, unpressurized and sealed. In this manner we minimize the leak rate by essentially negating the pressure differential from inside to outside, with all valves closed and blower off. With four internal air handlers the temperature remains relatively constant, thereby reducing the expansion and contraction of the internal air from day to night.

As noted in the previous post there are 144 pea plants growing in hydroponics. At the close of six weeks (from seed) they are at a peak maturity, meaning they will, in theory, provide the maximal uptake of carbon dioxide and production of oxygen. However, our math models suggest that these 144 plants will provide between two-thirds and three-fourths the CO2 sequestration required. This is by design, for we prefer to see Matthias’ CO2 production be reduced by an observable amount rather than brought to zero, where we would not know precisely the number of plants that did in fact offset his CO2 production.

In this manner we can take his personal CO2 production baseline over 58 hours (conducted earlier this year), establish an hourly rate, multiply by 7 days [14 days x 24 hrs x ppm per hour], and quickly gain a ballpark approximation for his peak level. We then monitor the real CO2 over this seven day period and compare: subtract the actual CO2 level after one week from the estimated peak, divide by square meters of plants or by the number of peas plants, and we have a rough estimate for CO2 sequestration by dwarf peas.

Finally, to validate this model we go one step further. On day 8 Matthias will harvest all of the peas, conduct a series of measurements (size, shape, mass) to assist in Atila’s research, retain some of the peas for his consumption, and then pass all remaining biomass through the airlock for external processing by Atila and Luna. As such, his second week will see Matthias without external air injection or CO2 sequestration of any kind. As we already know his baseline, we have estimated the ceiling and know that he will be within a safe level.

This final week gives us a comparison of our model vs reality, and a solid understanding of SAM itself in the context of plant growth with computer controlled CO2 injection, human CO2 generation, and then sans any scrubbing at all. This three prong approach provides a vital understanding as we look to a future in which we are living off of this planet and among the stars. And as with Biosphere 2, it also gives us a deeper appreciation for how our animal functions do interact with the plants of Earth each and every day.

Enjoy a few historic photos of the B2 Test Module, and Linda Leigh’s 1990 three weeks stay inside, followed by the informal gathering to send Matthias into his sealed mission.

Tomorrow morning, Monday, October 13, we will embark on a mission like none other at SAM–we will engage in the mission we envisioned nearly five years ago when Trent and I first put orbital sander to rusted metal.

Tomorrow morning, Monday, October 13, we will embark on a mission like none other at SAM–we will engage in the mission we envisioned nearly five years ago when Trent and I first put orbital sander to rusted metal.