The final hydroponic racks are complete!

After Sean and Luna built out prototype #4 earlier in the summer and decided that was the system that suited SAM best, Luna and Matthias got to work building three more copies in August. They were joined by Dr. Linda Leigh who was added to the SAM team in order to further her knowledge on hydroponic systems and be more involved at SAM. With their combined strengths they got to work assembling the racks.

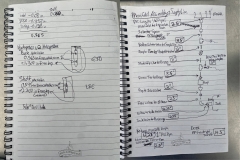

The first step was to build the skeleton of the rack. Using 80/20 they built up the sides, leveled the bottom and added the shelves. Once everything was level and secure they moved on to adding the plant trays, two per shelf. This involved meticulous and precise cutting of the trays, then cleaning up and gluing caps on the ends. Once they were satisfied with the end result of the trays, it was all about PVC. They built out the pump, intake manifold, return manifold and water drops for each shelf. This took the majority of the time, measuring, cutting, gluing, testing and putting together.

There were a lot of ideas how everything should get done and what the final product should look like. With a couple shipping delays the team was finally able to test the racks. To their amazement there were no significant issues with the system—no large leaks or anything that could not be fixed with a few turns of a union. With just 3 days left to spare, everything was ready for the tomato experiment to go in on September 2nd! —by Luna Powell, Site Manager and Greenspace Researcher at SAM