by Griffin Hentzen, ME

In any closed environment such as a house, school, or pressure vessel, carbon dioxide (CO2) builds up at a rate dependent on the volume of the space, the number of humans inside, and the degree of closure. With a spacecraft, we will assume complete closure, for our baseline design. After a certain amount of time, the increased CO2 levels can have adverse effects on the crew members. For this reason, all crewed spacecraft have some method of removing CO2 from the cabin air.

Sometimes a single-use system, called a non-regenerable CO2 removal system, is employed. You can find these on short duration spacecraft like SpaceX Crew Dragon or the Boeing Starliner. These systems are simple, but since you can’t regenerate them (remove the CO2 and re-use) on orbit, they are not well suited for long-duration missions.

This is why we are designing a regenerable CO2 removal system for SAM, one that has the capability of capturing (adsorbing) and then releasing (desorbing) CO2 when desired. These systems are in use on the International Space Station (ISS) and are planned for future space stations and long-term crewed missions. SAM will leverage the existing design of the 4-bed-CO2 removal system (4BCO2) currently in use on ISS as the primary CO2 system, under a technology license from NASA Marshall. This will enable SAM crews to remain sealed inside for long duration (multiple week) missions.

I have the honor and priveledge of working with Dr. James Knox, a world leading expert on carbon dioxide removal systems and NASA veteran of nearly three decades. He is working as a consultant with SAM through the University of Arizona.

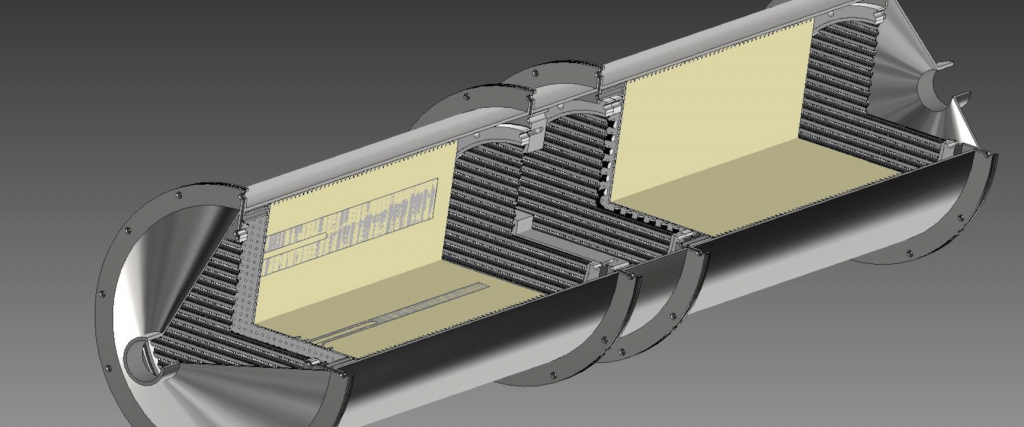

The 4BCO2 system employs a 4-bed, molecular sieve, thermal-vacuum, swing adsorption cycle. Let’s break that down. 4-bed simply means there are four main metal chambers that hold minerals called desiccants and zeolites. These minerals are very good at capturing water vapor and CO2 at the molecular level (thus, “molecular sieve”). The machine cycles between modes of adsorbing or desorbing (capturing/releasing) water vapor and CO2 based on the temperature and vacuum pressure we apply to them. When the bed is desorbing its CO2, we direct that CO2 down a specific line to permanently separate it from cabin air. Each bed will be adsorbing CO2 or water vapor, and then the cycle will switch, and the bed will “swing” into the other mode. Thus, 4-bed molecular sieve thermal-vacuum swing adsorption cycle.

We have designed or selected most of the essential components at a preliminary level, and are looking forward to seeing how the project progresses. The metal chambers and all flanges are designed by our team and will be manufactured by the University of Arizona’s Welding and Fabrication Facility. Major components such as the valves, blower, heat exchanger and vacuum pump will be Commercial-Off-The-Shelf (COTS) components that meet the required specifications.

Experiment | Design | Components | Assemble | Fabrication | Operation (coming soon)