As we move into the test phase, we are running a series of tests to ensure that certain custom components will perform as expected. One component of significance is the metal chambers that will hold the desiccant and sorbents. In order to remove a given amount of CO2, the system needs to move a specific volume of air in a given period of time.

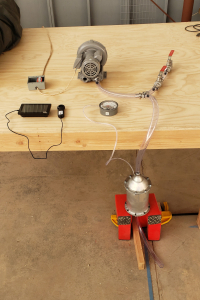

The silica and zeolite beads in the beds cause a significant amount of resistance to that airflow, so it is essential we can calculate the blower capacity for the given, required flowrate. For this immediate test I am repurposing metal chambers and valves used in a previous senior design project (2022), with a new, small blower.

The silica and zeolite beads in the beds cause a significant amount of resistance to that airflow, so it is essential we can calculate the blower capacity for the given, required flowrate. For this immediate test I am repurposing metal chambers and valves used in a previous senior design project (2022), with a new, small blower.

We will measure the pressure drop (the amount of pressure needed to push air through at a given rate) across the metal chamber as well as the flowrate of air. We will control the flowrate by incrementally opening and closing a bleed valve that enables a limited portion of the air to bypass the chamber entirely.

Once we have the correlation between the flowrate and the pressure drop, we will be able to predict the pressure drop in chambers of different sizes and different flowrates. This will allow us to determine the requirements for the final blower we select.

Experiment | Design | Components | Assemble | Fabrication | Operation (coming soon)